Energy-intensive industry must jump-start low-CO₂ technologies to reach climate targets – study

Improving efficiency continues to be important, but is insufficient to align steel, cement and chemical businesses with the path to a climate neutral economy by 2050 – the target many countries, including Germany, have signed on to – say researchers from Agora Energiewende and the Wuppertal Institute for Climate, Environment and Energy in a joint study.

“We additionally need innovation leaps when it comes to key low-CO₂ technologies,” said Agora head Patrick Graichen. The researchers say that now is the time for the government to introduce the right policy framework to make this happen, as the business case for such technologies is lacking.

More than half of the energy and emission-intensive facilities in steel and chemicals production, and a third of those in the cement industry, have to be modernised over the coming ten years, they write. “Between 2020 and 2030, there will be a major reinvestment phase in industry – this is a great opportunity for climate action,” said Manfred Fischedick, vice president of the Wuppertal Institute. Businesses now need the right framework to make future-oriented investments, he added. “Otherwise, there is a risk of an investment backlog or the danger of mismanagement and lock-in effects.”

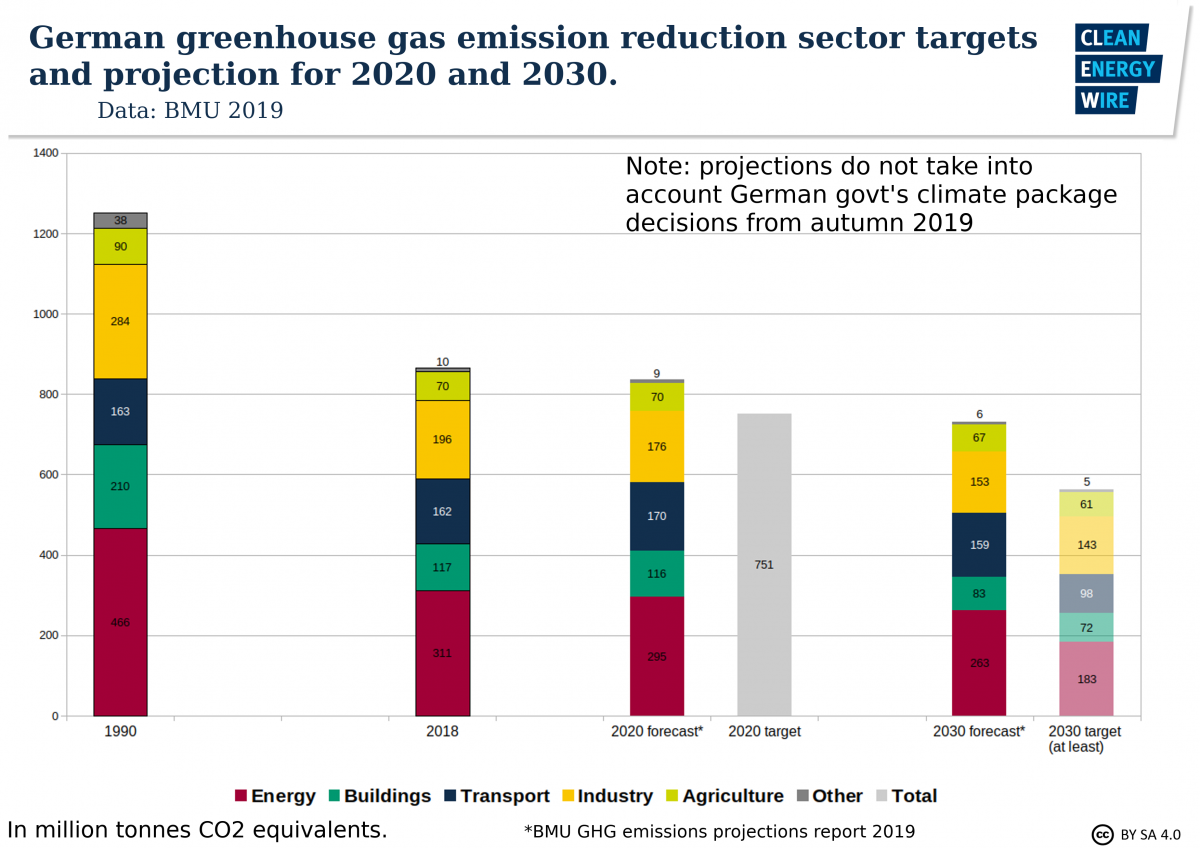

Basic industries are a “cornerstone for prosperity in Germany.” They directly employed more than 500,000 people and made revenues of 2,050 billion euros in 2017. However, greenhouse gas emissions from the entire industry sector have fallen only slightly over the past twenty years, says the study. The German government has set the target for the sector to cut emissions in half by 2030, compared to 1990 levels. By 2018, industry had managed to reduce them by about 30 percent.

The majority of these emissions cannot be cut with conventional methods because they are not directly related to burning fossil fuels but are released during the chemical or physical transformation of materials (so-called process emissions). It is theoretically possible to run most industry processes on renewable power – including its indirect use by making synthetic hydrogen. But switching current production levels to renewable energies would require enormous amounts of energy due to conversion losses.

Need emergency programme to scale up low-CO₂ technologies

Agora Energiewende and the Wuppertal Institute propose an emergency programme to scale up key climate-friendly technologies necessary to make the German steel, chemical and cement industries global pioneers.

They say one option could be to introduce a “very high” floor price in the EU Emissions Trading System (ETS) in combination with a border adjustment regime. This could lead to issues, such as disputes with trading partners.

Option two would be a policy mix of instruments, including a carbon contract for difference, a CO₂ price on the industries’ consumer products, a green hydrogen quota for gas traders, green finance instruments, and a climate-friendly government procurement strategy. The future mix of instruments for a climate-neutral industry, the question of national or European implementation and the effects on employees must be discussed in detail with stakeholders from politics, industry, trade unions and civil society, say the researchers.

*Like Clean Energy Wire and Agora Energiewende, Agora Energiewende is funded by the Stiftung Mercator and the European Climate Foundation.