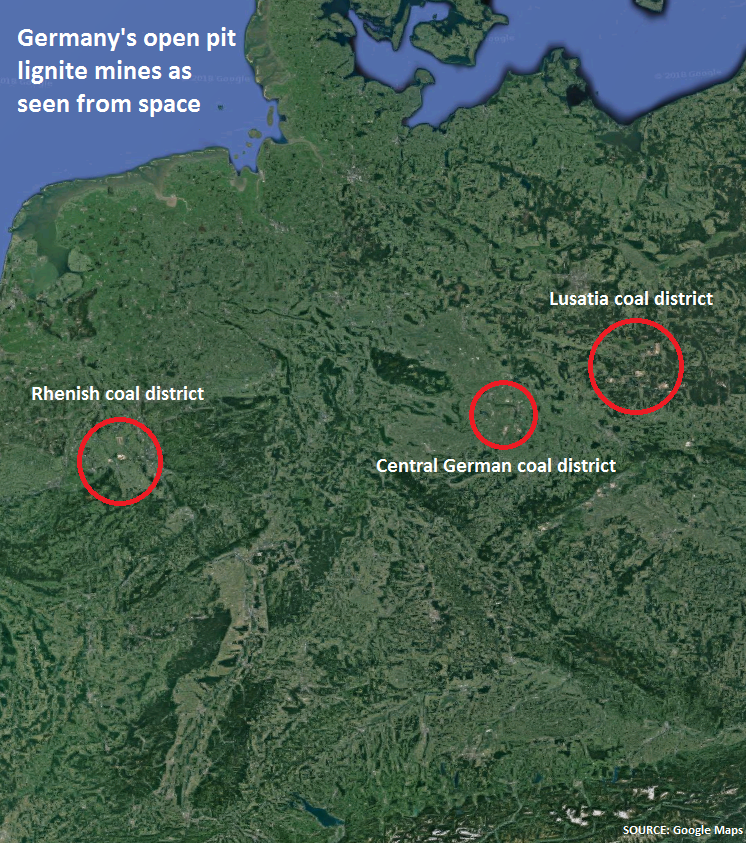

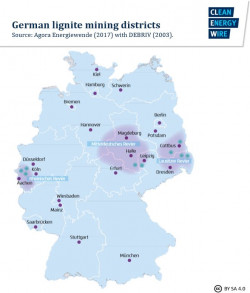

Germany’s three lignite mining regions

Germany used to be the largest lignite producer in the world since the beginning of industrial lignite mining. However, China overtook the country and production today far outstrips that in Germany. The softer and moister lignite (also called brown or soft coal) has a lower calorific value than hard coal and can only be mined in opencast operations. When burned, it is more CO2 intensive than hard coal.

To date, opencast lignite mining has altered 179,490 hectares of countryside in Germany. Since 1924, 313 settlements have been lost to lignite mines in the country.

Source: Agora Energiewende**/Google Maps.

One of the most contested aspects of the phase-out of brown coal is how it will affect the social and economic well-being of the people living in the mining regions. Hence the official name of the coal exit commission: “Commission on Growth, Structural Change and Employment”.

Data on direct employment in brown coal operations is provided by the German federal association of the lignite industry (DEBRIV) (here). In May 2018, a 20,821 people were employed in the lignite sector (including mining, power plant operation, and revegetation of former mines). Across Europe, coal mining (hard coal and lignite) provides 185,000 jobs, most of them in Poland, Germany, Czech Republic, and Romania (2015 figures). This report by the European Commission on EU coal regions provides data and background on employment and challenges of Europe's coal mining districts.

Source: Ökoinstitut.

Several attempts have been made to estimate the number of jobs indirectly dependent on the lignite sector in Germany (see an overview on pp 86-89 here). The most recent calculations were published by the Rhineland-Westphalia Institute for Economic Research (RWI) in 2018, and are used to inform the members of the coal commission.

RWI concludes that up to 32,000 jobs depend on the brown coal sector in the mining districts, and that the eastern German lignite mining regions in particular are battling with low levels of industrialisation, weaknesses in the service sector, and a very low innovation intensity (see the basis for their analysis here).

Two-thirds of people employed in the lignite sector are older than 45 (2015 data). According to a 2018 study conducted by the Institute for Applied Ecology (Ökoinstitut) for the Federal Environment Agency (UBA), 63 percent of these employees will be retiring by 2030. This means that compulsory redundancies among the existing workforce could largely be avoided if coal power generation is reduced in accordance with Germany’s 2030 climate target, the researchers say. But while this could make phasing out coal operations for today’s employees easier, it wouldn’t solve the economic problems of the regions, the RWI researchers stated in their study.

Source: Agora Energiewende.

Lusatia (Brandenburg and Saxony)

Lusatia comprises a region in the eastern German states of Brandenburg and Saxony, and in south-western Poland. It is home to around 1.3 million people. Lusatia is a very rural area. Its largest city and economic centre is Cottbus (around 100,000 inhabitants). In 2015, the GDP of the Lusatian mining region was estimated at 31,425 million euros.

Lignite mining in Lusatia began in 1860. It was first used to power steam engines and trains, and in clothes manufacturing. In 1882, Europe’s first brown coal briquette factory was opened in Lusatia. By now, 136 villages and communities had to be resettled to allow for lignite mines in Lusatia to be expanded.

Larger scale lignite mining began around 1900, and saw the establishment of four family-owned mining cooperatives, three of which were forced out of business by the Nazis because their owners were Jewish. After the Second World War, when eastern Germany was under Russian military administration, and in the ensuing GDR years, all mining and power plant operations were nationalised. After Germany’s reunification in 1990, many mines and power plants were closed down, and the remaining operations were privatised.

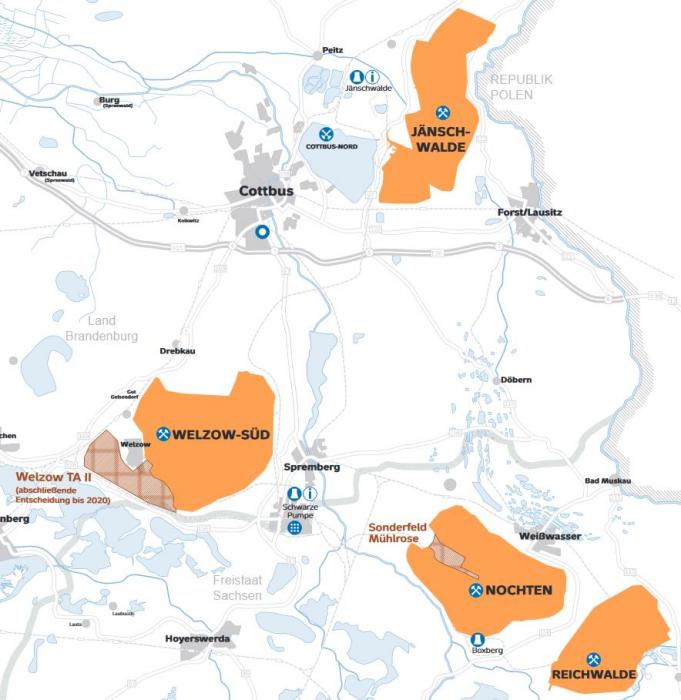

Today, the energy company LEAG operates four opencast mines in Lusatia. The Jänschwalde and Welzow-Süd mines are located in the state of Brandenburg; Nochten and Reichwalde are on the territory of Saxony. These four mines contain around 825 million tonnes of lignite, according to LEAG. This energy company also operates four lignite-fired power plants in the area with a combined capacity of over 8 gigawatts (GW), and a 400-km rail network to transport coal from the mines to the power plants.

The lignite-fired power plants of Jänschwalde, Boxberg IV and III, and Schwarze Pumpe produced 49 terawatt-hours (TWh) of electricity and emitted 54.9 million tonnes of CO2 in 2015.

LEAG is owned by the Czech energy company EPH and PPF Investments. The latter entity’s controlling shareholder is Tomáš Brzobohatý.

After the extraction of coal finishes, the lignite districts will be revegetated. In Lusatia, LEAG is planning to plant forests on 53 percent, lakes on 25 percent, fields on ten percent, and roads and other touristic infrastructure on the remaining 12 percent of the affected area.

Source: LEAG, 2017.

Structural change, employment, and future prospects of the region

According to LEAG, around 8,000 people work for its Lusatian mining and power plant businesses.

DEBRIV’s records show that LEAG has 8,049 employees in Lusatia, and that another 417 work for the Lausitz [Lusatian] and Central German Mining Administration Company (LMBV), which is mainly in charge of revegetating and rehabilitating the landscape after a mine is closed.

A 2018 RWI publication calculates that in Lusatia 13,245 jobs are directly or indirectly related to the brown coal sector.

State provisions for lignite mining

The Brandenburg state government, under whose jurisdiction the mining activities at Jänschwalde and Welzow-Süd fall, has made it clear in an update to its Energy Strategy 2030 (dated July 2018) that it considers lignite mining and lignite-fired power generation to be a “vital bridging technology” in the energy transition, and a business that benefits the regional economy. It opposes any “abrupt” structural or social changes brought about by regulations and state interventions. There is no provision against new mines in Brandenburg’s current state development plan.

In its 2012 energy and climate programme, the state government of Saxony, responsible for the mines in Nochten and Reichwalde, argues that lignite is a “domestic, subsidy-free” energy source that helps generate secure and cost-effective power, and that its closed-loop value chain benefits the region,. Saxony’s lignite reserves could last for several generations. Due to its “long-lastingness, reliability, security, […] cost-efficiency, independence, and societal acceptance,” lignite could not be rivalled by any other energy source, the programme reads. Since climate action requires the reduction of lignite CO2 emissions, technologies that increase the efficiency of power plants, along with carbon capture and storage, would have to be employed, the document says.

Saxony’s current state development plan allows for the further expansion of the state’s lignite mines.

Jänschwalde:

- Size: 80 km2

- Amount of lignite mined: 8-10 million tonnes per year (7.1 million in 2017)

- Depth of lignite deposits: around 95m

- Start of operations: 1974

- End of operations: expected in 2023

- Resettlements because of mine*: 5 villages

Welzow-Süd:

- Size: 108 km2

- Amount of lignite mined: 20 million tonnes per year (22.1 million in 2017)

- Depth of lignite deposits: up to 120m

- Start of operations: 1959

- End of operations: Coal extracted from the current mine (Teilabschnitt I), supplying the Schwarze Pumpe power plant, is calculated to last until 2027-2030.. A further expansion of the Welzow-Süd mine into Teilabschnitt II (see map) would enable mining to continue until 2045-2050. A decision on further expansion is pending, and will have to be made by 2020, LEAG says.

- Resettlements because of mine: 12 villages with 2,886 inhabitants

Nochten:

- Size: 107 km2

- Amount of lignite mined: 18.5 million tonnes in 2017; 30 million tonnes per year together with Reichwalde

- Depth of lignite deposits: up to 100m

- Start of operations: 1968

- End of operations: around 2045

- Resettlements because of mine: 4 villages, 195 people; in the future: Mühlrose, 200 people

Reichwalde:

- Size: 55 km2

- Amount of lignite mined: 13.2 million tonnes in 2017; 30 million tonnes per year together with Nochten

- Depth of lignite deposits: up to 100m

- Start of operations: 1985 (paused between 1999 and 2010)

- End of operations: expected in 2045

- Resettlements because of mine: 8 villages, over 244 people

* The data on resettlements refers to the currently mined area, not to the whole mine, which as a rule has led to the destruction of many more villages. Accurate figures are often lacking on the number of people who had to re-settle because of mine expansion.

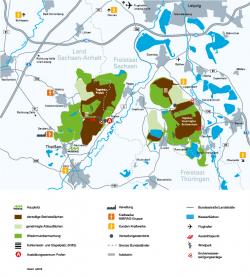

Central German mining district (Saxony and Saxony-Anhalt)

The Central German mining district is located in the states of Saxony and Saxony-Anhalt in the former East Germany. It is the oldest of Germany’s lignite mining regions. Until the 1960s, it was also the most important region, contributing between 40 and 50 percent to the total amount of lignite mined in Germany.

Larger scale lignite mining began around 1900, with several companies operating the mines, the power plants, the briquette factories and the beneficiation activities. Chemical beneficiation of brown coal is one of the specialities of the Central German district. Coal from the Central German district has a high heating value and a low CO2 emission factor, but its sulphur content of 1.7 percent causes more corrosive wear to the power plant machinery.

After the Second World War, when East Germany was under Russian military administration, and also in the following GDR years, all mining and power plant operations were nationalised. After reunification in 1990, many mines and power plants were closed down and the remaining operations were privatised.

Today, the mining district comprises the Profen, Vereinigtes Schleenhein (both operated by MIBRAG), and Amsdorf (operated by Romonta) mines. The coal from Profen and Vereinigtes Schleenhain (around 10 percent of the lignite mined in Germany) is mainly used to supply the power plants at Schkopau and Lippendorf, which are operated by EnBW, LEAG, and Uniper/Saale-Energie, and partially owned by EPH.

In 2015, the plants at Schkopau and Lippendorf produced 15.8 TWh of electricity and emitted 15.7 million tonnes of CO2.

MIBRAG is 100% owned by the Czech investor EPH.

The Profen and Vereinigtes Schleenhain mines contain 388 million tonnes of lignite (2015). If mined continually at a rate of 8-10 million tonnes per year, the reserves would last until 2032 in Profen and until 2041 in Schleenhain.

Source: MIBRAG, 2018.

The smaller mine at Amsdorf is operated by the chemicals company Romonta, which uses the highly bituminous coal mainly to manufacture crude montan wax, of which it is one of the world’s largest producers.

Structural change, employment, and future prospects of the region

In 2015, the GDP of the Central German mining district was estimated at 55,619 million euros.

MIBRAG employs 1,860 people in its mines and power plants in the Central German brown coal district. According to the RWI, a total of 2,414 people are employed in the Central German mining district, and an estimated 3,862 jobs depend directly or indirectly on the brown coal sector there. The researchers find that the Central German lignite district has a higher innovation and growth potential, helped by the fact that it is located close to the big cities of Leipzig and Halle.

State provisions for lignite mining

The coalition government of the state of Saxony-Anhalt (CDU, SPD, and Green Party, responsible for the mines in Profen and Amsdorf) rules out the opening of new lignite mines for energy generation purposes (but not for other chemical uses). However, the government has also decided not to support the planning of new mines until 2021.

In its 2012 energy and climate programme, the government of Saxony, responsible for the mines at Vereinigtes Schleenhain, calls lignite a “domestic, subsidy-free” energy source that helps provide secure and cost-effective power, and says that its closed-loop value chain benefits the region. Lignite reserves in Saxony could last for several generations. Due to its “long-lastingness, reliability, security, […] cost-efficiency, independence, and societal acceptance,” lignite could not be rivalled by any other energy source, the programme reads. Since climate action requires the a reduction of lignite CO2 emissions, technologies that increase the efficiency of power plants, along with carbon capture and storage, would have to be employed, the document says.

Saxony’s current state development plan allows for the further expansion of the state’s lignite mines.

Profen:

- Size: 17 km2

- Amount of lignite mined: 8 million tonnes per year

- Start of operations: 1941

- End of operations: 2030-2035

- Resettlements because of mine*: 6 villages, over 800 inhabitants

Vereinigtes Schleenhain:

- Size: 17 km2

- Amount of lignite mined: 11 million tonnes per year

- Start of operations: 1949

- End of operations: around 2040

- Resettlements because of mine*: Heuersdorf (300 inhabitants; 2009); in the future possibly Pödelwitz and Obertitz (100 people), if another 35 million tonne coal deposit is accessed

Amsdorf:

- Size: 2 km2

- Amount of lignite mined: 0.3 million tonnes per year (2015)

- Depth of lignite deposits: around 80m

- Start of operations: 1959

- End of operations: expected in 2025/2030

- Resettlements because of mine*: not required

Rhenish mining district (North Rhine-Westphalia, NRW)

The history of brown coal mining in the Rhenish mining district, located in Germany’s most densely populated (non-city) state of North Rhine-Westphalia between Aachen and Cologne (see map), dates back to the 19th century, when costs feel due to the adoption of new pumping and compactor technologies and brown coal became a competitive energy source, at first mostly in the form of coal briquettes. Electricity generation from lignite began in a small lignite-fired power plant in Frechen in 1892, and the first 1 MW plant (Kraftwerk Berggeist) opened in 1899 near the sugar factory in Brühl. But even in the 1950s, production of brown coal briquettes used in factories and homes was still a major business.

The Rheinisch-Westfälisches Elektrizitätswerk AG (RWE, founded in 1898) entered the lignite business when in 1906 it bought the Berggeist power plant. The three remaining opencast mines in the Rhenish district still belong to RWE Generation SE.

In the Rhenish mining district, RWE supplies (and operates) the lignite-fired power plants at Neurath, Niederaußem, Weisweiler, and Frimmersdorf. The Frimmersdorf plant was transferred into the security stand-by reserve in 2017. The 4.4 GW power plant at Neurath (Germany’s largest) alone emitted 31.3 million tonnes of CO2 in 2016. The plants at Niederaußem (3.6 GW capacity) and Weisweiler (1.9 GW) emitted 43 million tonnes of CO2 in 2016.

Coal mining and the related industry has shaped the landscape in North Rhine-Westphalia for over 100 years. Some 50 villages or parts of villages had to be evacuated to make room for the expanding lignite mines. The Hambach mine (which is the largest mine in Germany) in particular has been the subject of decades of protests. Since 2012, protesters have occupied parts of the Hambacher Forst, a 1,200 ha forest that has largely fallen victim to the expanding lignite mine. The legal battle waged by environmental organisations to protect the forest has so far proved futile.

Source: Wikimedia Commons.

Source: Wikimedia Commons.

Structural change, employment, and future prospects of the region

A total of 8,961 people are working in the Rhenish district’s lignite mines and power plants, and 14,338 jobs are directly or indirectly induced by the brown coal sector, the RWI says.

The Rhenish mining district’s GDP amounted to 79,303 million euros in 2015.

With the nearby cities of Aachen and Mönchengladbach and its proximity to Cologne, the Rhenish lignite district has comparatively favourable conditions for non-mining industry and businesses that could soften the economic and social effects of the mines’ closure.

State provisions for lignite mining

The state government of North Rhine-Westphalia, responsible for the lignite mines at Inden, Hambach, and Garzweiler, says in its state development plan that the further expansion of these mines is not necessary.

In NRW, the state government decided in March 2014 to cut lignite production by 1.3 billion tonnes, thereby saving 1,400 people from the need to relocate. Mining activities are set to continue until at least 2030. A new government, elected in 2016, said that it would use brown coal as a bridging technology but honour the existing mining permissions.

Garzweiler II:

- Size: 48 km2

- Amount of lignite mined: 35 million tonnes per year

- Depth of lignite deposits: 40-210m

- Start of operations: 2006

- End of operations: expected in 2045

- Resettlements because of mine*: Six villages resettled by 2015;Unterwestrich, Oberwestrich, Kuckum, and Beverath with around 800 residents planned for 2027-2028; with a total of 7,618 inhabitants

Hambach:

- Size: 85 km2

- Amount of lignite mined: 40 million tonnes per year

- Depth of lignite deposits: around 450m

- Start of operations: 1978

- End of operations: expected in 2045

- Resettlements because of mine*: Four villages already resettled; two more are underway: Manheim (2022) and Morschenich (2024)

Inden:

- Size: 17 km2

- Amount of lignite mined: 19 million tonnes per year

- Depth of lignite deposits: around 230m

- Start of operations: 1982

- End of operations: expected in 2030

- Resettlements because of mine*: 10 villages, 5,760 inhabitants

* The data on resettlements refers to the currently mined area, not to the whole mine, which as a rule has led to the destruction of many more villages. Accurate figures are often lacking on the number of people who had to re-settle because of mine expansion.

** Agora Energiewende and the Clean Energy Wire are both funded by Stiftung Mercator and the European Climate Foundation.